Description

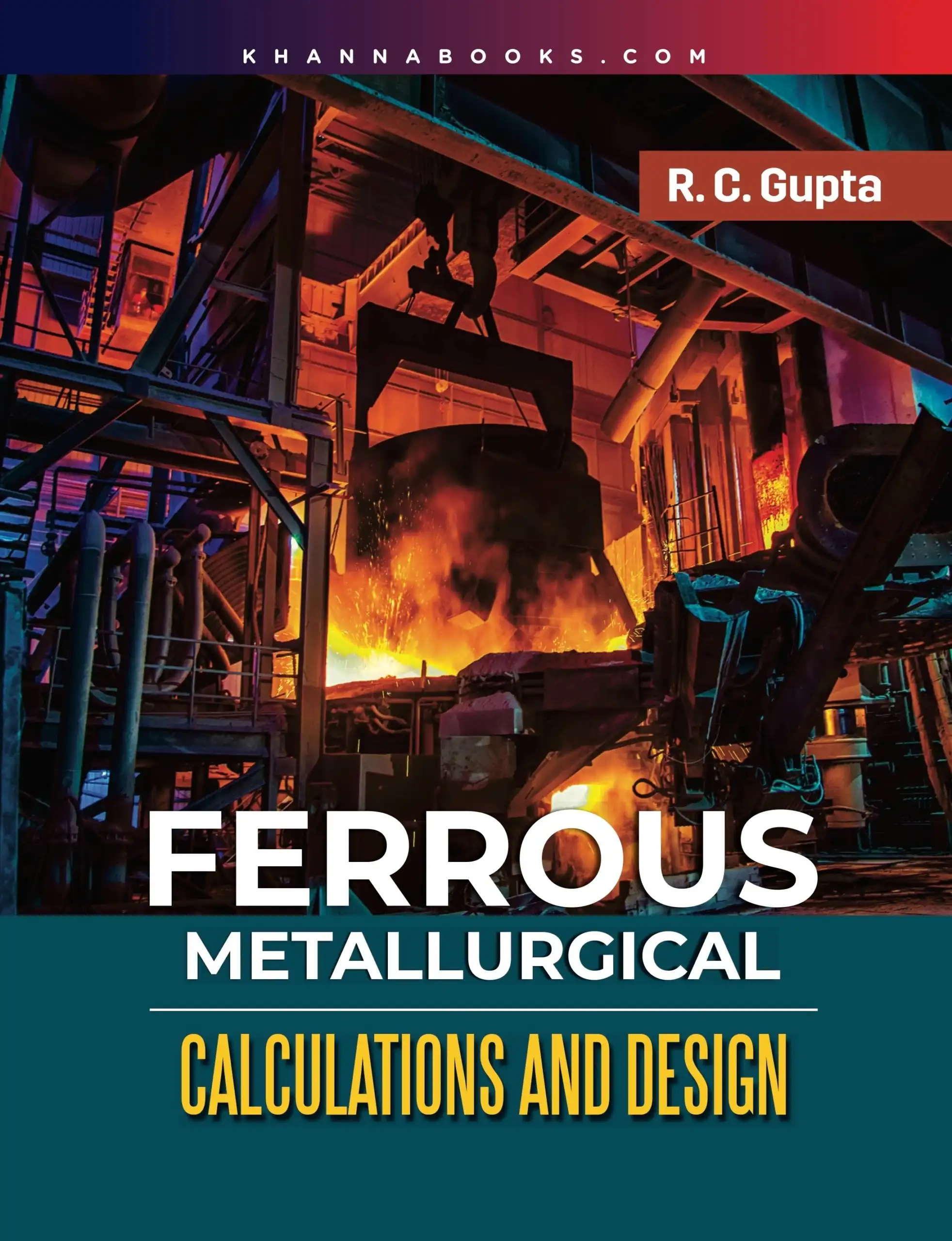

This book is a unique combination of ferrous metallurgical calculations and unit design. The book is divided in two arts each having eight chapters.

The part one on ferrous metallurgical calculations gives method to calculate mass balance, chemical analysis of the product and waste materials including exit gases. This part one covers Coal & It’s Properties, Combustion of Fuels, Coke Making, Iron Ore Agglomeration, Blast Furnace Iron Making, Alternate Methods of Iron Making, Ferroalloy Preparation and Melting Metal & Alloys.

The second part on Ferrous Metallurgical Unit Design may be a globally first attempt to provide method of estimating basic design dimensions of some metallurgical units. This part covers Chimney & Draught, Coke Oven, Blast Furnace, DRI Kiln, Ladle Cupola, Basic Oxygen Steel Making Furnace, and Electric arc Furnace.

In addition, the appendices provide weight, Measure & Science Laws, Mathematical Formulae, Unit Conversion Tables, Useful Data, Commonly Used Materials, Raw, Materials for Iron & Steel Making, Fuels and their Properties and Steel Plant Waste materials.

Keys features

1. A useful book for Academic Staff & Students in Metallurgical Engineering, Still Plant Executives, Metallurgical Consultants, Steel Plant Managers, Chartered Engineers, and Auditors.

2. A Metallurgical Engineering book giving calculation method for mass balance, product & waste analysis in various ferrous metallurgical processes.

3. A first book to give method for designing metallurgical units e.g. coke oven, blast furnace, DRI Kiln, BOF, EAF, Ladle, Cupola etc.

4. Each chapter starts with introduction to highlight importance before giving calculation or design & each chapter gives projects for students. Some reference for further reading is also given at the end of chapters.

Table of Contents

Part A: Ferrous Metallurgical Calculations

Chapter 1: Coal and its Properties.

Chapter 2: Combustion of Fuels.

Chapter 3: Coke Making.

Chapter 4: Iron Ore Agglomeration.

Chapter 5: Blast Furnace Iron Making.

Chapter 6: Alternate Methods of Iron Making.

Chapter 7: Ferroalloy Making.

Chapter 8: Melting Metals & Alloy.

Part B: Ferrous Metallurgical Unit Design.

Chapter 9: Chimney & Draught.

Chapter 10: Coke Oven Dimensions.

Chapter 11: Blast Furnace Dimensions.

Chapter 12: DRI Kiln Dimensions.

Chapter 13: Ladle Dimensions.

Chapter 14: Cupola Dimensions.

Chapter 15: Basic Oxygen Steel Making.

Chapter 16: EAF Steel Making.

Appendix

Author

Prof. R C Gupta is an alumni, Former Professor and Head, Department of Metallurgical Engineering (Advanced Centre in Metallurgy), Institute of Technology (now IIT-BHU), Banaras Hindu University, Varanasi (India). In his four decades (1970-2010) teaching and research carrier he guided many students for their PhD, M. Tech., and B. Tech. degree in Metallurgy. He held various positions in national & international forums including Ministry & Forest (Delhi-GOI) & Pollution Control Board (Bhubaneswar-Odisha State).

The Author is globally known by his three popular PHI (Delhi) textbooks: Theory & Laboratory Experiments in Metallurgy ( 2009 & 2025), Energy & Environmental Management in Metallurgical Industries (2012), and Fuels Furnaces & Refractories (2016). His chapter on Energy Resources, Its Role, and Use in Metallurgical Industries in Elsevier’s publications (2014 & 2024) on Treatise in Process Metallurgy (Chief Ed. Sheshadri Seetharaman) has made global imprint. In view of his books and other research publications (>140 nos.) the author is included in world top 2% scientist prepared by a Group of Professors at Stanford University (USA) in 2020.

![Mathematics I Calculus and Linear Algebra [For Computer Science Engineering Branches] (English)](https://khannabooks.com/wp-content/uploads/2023/10/978-93-91505-27-1.jpg)

Reviews

There are no reviews yet.